Automatic segmented stator winding machine for BLDC motor open linear stator

1. Description:

The automatic segmented stator winding machine adopts needle winding technology with 3 needles, is used for open linear segmented stator coil winder, It is an improved coil winding making manufacturing technique, increase the performance of permanent magnet electrical machines and reduce cost, Segmenting the stator core offers the possibility to simplify the winding process, to increase slot fill factor or to minimize wastage of electrical steel. During winding, it can achieve multi-tapping (set on the HMI), wire damping, wire cutting.

The slot No. and turn No. can be set on HMI.

2. Application:

The stator winding machine suitable for BLDC motor stator manufacturing, a stator composed of similar stator segments and to a method for producing a stator from stator segments, wherein the stator segment comprises a laminated core that has a plastic layer which is arranged between the winding region of the stator winding and the laminated core for electrically insulating the winding region from the laminated core.

3. Specification:

| Product name: | Automatic segmented stator coil winding machine |

| Wіrе dіа.: | ф0.2-Ф1 .5mm(can be customized if special) |

| Stator stackheight: | 10-80mm |

| Stator length: | 60-300mm |

| Speed range: | 0-800RPM adjustable |

| Servo mechanism: | 1pc 3KW winding motor with brake, 2pcs 750W lef-right and wire arraying motor |

| Pole No.: | multi poles |

| Power: | 20KW |

| Air pressure: | 0.5-1MPa |

| Voltage: | 380V/50Hz three phase four wires |

| Dimension: | 1300 mm X 1200 mm X 1600mm |

| Weight: | 800KG |

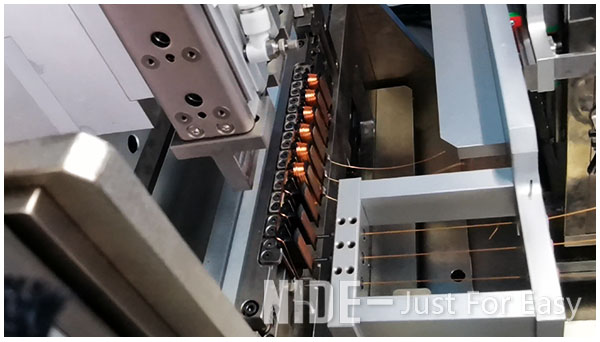

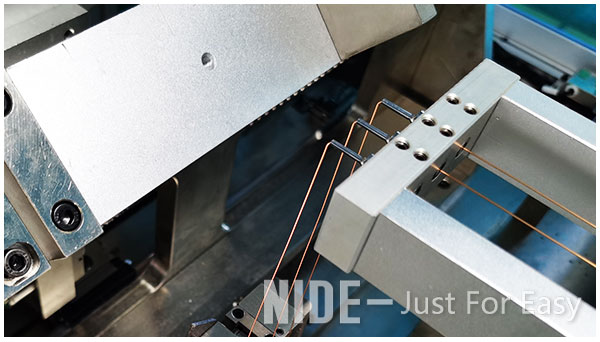

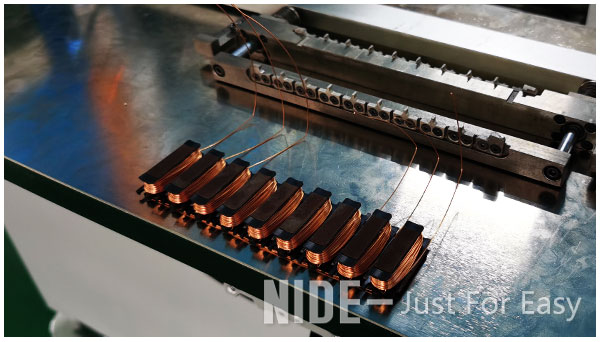

4. Segmented stator winding machine Picture show

The automatic segmented stator winding machine adopt needle coil winding technology

The automatic segmented stator winding machine has 3 coil winding needles

The motor segmented stator after coil winding

5. Automatic BLDC motor segmented stator needle coil winding machine video